Farming is a complex and rewarding endeavor that demands attention to detail. One crucial aspect often overlooked is the maintenance of agricultural equipment, particularly seed drills. In this article, we’ll delve into comprehensive seed drill maintenance tips designed to ensure the longevity and optimal performance of these essential tools.

Introduction

A. Brief Overview of Seed Drills

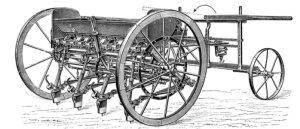

Seed drills play a pivotal role in modern agriculture, facilitating efficient and precise seed placement during planting. These machines have revolutionized farming by enhancing seed distribution and reducing manual labor.

B. Importance of Seed Drills Maintenance

While seed drills are robust tools, regular maintenance is paramount for their sustained performance. Proper upkeep not only extends the lifespan of the equipment but also contributes to higher crop yields and cost-effective farming practices.

Regular Cleaning Procedures

A. Cleaning Seed Compartments

One of the fundamental maintenance steps is cleaning seed compartments thoroughly. Removing residual seeds and debris prevents blockages and ensures a smooth planting process.

B. Removing Debris from the Mechanism

Inspecting and clearing debris from the drill’s mechanical components is essential. This prevents wear and tear, maintaining the efficiency of the entire system.

C. Lubricating Moving Parts

Regularly lubricating moving parts, such as gears and bearings, minimizes friction and reduces the risk of breakdowns. It’s a simple yet effective way to enhance the longevity of your seed drill.

Inspection of Seed Tubes

A. Checking for Blockages

Examining seed tubes for blockages is crucial. Even a minor obstruction can disrupt the seed distribution pattern, leading to uneven planting.

B. Ensuring Proper Alignment

Misaligned seed tubes can result in uneven seed placement. Regularly checking and correcting alignment issues is key to achieving uniform crop growth.

C. Replacing Damaged Tubes

Any sign of damage to seed tubes should not be ignored. Prompt replacement of damaged tubes prevents potential seeding problems and ensures precision in planting.

Calibration Process

A. Importance of Calibration

Calibrating your seed drill is akin to fine-tuning a musical instrument. It ensures accurate seed placement and spacing, directly impacting crop yield.

B. Steps to Calibrate a Seed Drill

Calibration involves adjusting the drill settings to achieve the desired seeding rate. Follow manufacturer guidelines to calibrate your seed drill correctly, considering factors like seed size and type.

Blade and Opener Maintenance

A. Sharpening Blades

Sharp blades are essential for cutting through soil and plant residue. Regularly sharpening blades maintains the drill’s cutting efficiency, contributing to a smooth planting process.

B. Inspecting Openers for Wear and Tear

Openers bear the brunt of the drilling process. Regular inspections help identify signs of wear and tear, allowing for timely replacement and preventing costly damage.

C. Replacing Worn-Out Parts

Ignoring worn-out parts can lead to extensive damage to your seed drill. Replace any components showing signs of wear to ensure optimal performance during planting.

Depth Adjustment

A. Understanding the Importance of Seed Depth

Seed depth significantly influences germination and crop development. Understanding and adjusting seed depth settings according to soil conditions is vital for a successful harvest.

B. Adjusting Seed Depth Settings

Factors like soil type and moisture levels necessitate periodic adjustments to seed depth settings. Regularly check and modify settings to suit the specific requirements of your farming environment.

Tire and Wheel Maintenance

A. Inspecting Tire Pressure

Proper tire pressure is critical for the stability and maneuverability of your seed drill. Regularly check and adjust tire pressure to prevent uneven wear and ensure smooth operation.

B. Lubricating Wheel Bearings

Wheel bearings undergo significant stress during field operations. Lubricating them regularly minimizes friction, reduces wear, and extends the lifespan of the wheels.

C. Replacing Damaged Tires

Damaged tires compromise the seed drill’s performance and can lead to accidents. Promptly replace any tires showing signs of wear or damage.

Electronic Components Check

Modern seed drills often come equipped with electronic components. Regularly test sensors and monitors to identify and address any issues before they affect planting accuracy.

B. Troubleshooting Electronic Issues

Understanding the basics of electronic components is essential. Troubleshoot and address electronic issues promptly to avoid disruptions during planting season.

Storage Tips

A. Storing Seed Drill in the Offseason

Proper storage during the offseason prevents exposure to harsh weather conditions. Store your seed drill in a sheltered space to protect it from the elements.

B. Protecting Against Rust and Corrosion

Apply rust inhibitors and protective coatings to vulnerable metal parts before storage. This simple step safeguards your seed drill against rust and corrosion, preserving its structural integrity.

Importance of Timely Maintenance

A. Maximizing Seed Drill Lifespan

Regular maintenance enhances the overall lifespan of your seed drill. Investing time in upkeep pays off with a more extended period of reliable service.

B. Ensuring Optimal Performance During Planting Season

Well-maintained seed drills ensure precision and efficiency during planting, contributing to higher crop yields and minimizing the risk of mechanical failures during critical farming periods.

Cost-Efficiency Benefits

A. Reducing Repair Costs

Proactive maintenance minimizes the need for extensive repairs, saving you money in the long run. Addressing issues promptly prevents small problems from escalating into costly repairs.

B. Enhancing Overall Farm Productivity

A well-maintained seed drill directly contributes to overall farm productivity. Consistent planting accuracy translates to uniform crop growth and improved harvests.

Common Mistakes to Avoid

A. Neglecting Regular Maintenance

Neglecting routine maintenance is a common pitfall. Regularly allocate time for seed drill upkeep to avoid preventable breakdowns and disruptions.

B. Ignoring Warning Signs

Unusual sounds, vibrations, or changes in performance are warning signs. Ignoring these signals can lead to more significant issues. Address concerns promptly to maintain optimal functionality.

Expert Advice

A. Seeking Guidance from Agricultural Experts

Don’t hesitate to seek advice from agricultural experts. Their insights can offer valuable tips on maintaining your seed drill and optimizing its performance.

B. Joining Online Forums and Communities

Online forums and communities provide platforms for sharing experiences and learning from fellow farmers. Engage with these platforms to gain valuable insights into effective seed drill maintenance practices.

Environmental Considerations

A. Eco-Friendly Seed Drill Maintenance Practices

Implement eco-friendly maintenance practices to minimize the environmental impact. Choose lubricants and cleaning agents that are environmentally friendly to align with sustainable farming practices.

B. Sustainable Farming Approaches

Consider incorporating sustainable farming approaches into your maintenance routine. This includes exploring cover cropping and reduced-tillage methods that benefit both the environment and your farming operations.

Conclusion

A. Recap of Key Maintenance Tips

Regular cleaning, thorough inspections, and proactive adjustments are the pillars of effective seed drill maintenance. Following these tips ensures your seed drill remains a reliable and indispensable tool on your farm.

B. Encouragement for Farmers to Prioritize Seed Drill Upkeep

Prioritizing seed drill maintenance is an investment in the success of your farming operations. By dedicating time and effort to upkeep, you’re safeguarding your equipment and ensuring consistent, high-quality yields.

FAQs

Q: How often should I clean my seed drill?

A: Cleaning your seed drill after each use is recommended to prevent the accumulation of debris and ensure optimal performance

Q: Can I use any lubricant for my seed drill?

A: It’s best to use lubricants recommended by the manufacturer to ensure compatibility with the drill’s components.

Q: What signs indicate that my seed tubes need replacement?

A: Any cracks, bends, or visible damage on seed tubes are indicators that replacement is necessary for efficient seed distribution.

Q: Is calibration really necessary for seed drills?

A: Yes, calibration is crucial for achieving accurate seed placement and optimizing crop yield.

Q: How can I join online forums for farming advice?

A: You can find agricultural forums on platforms like Reddit or specialized farming communities. Simply create an account and start engaging with fellow farmers.